Engine Performance

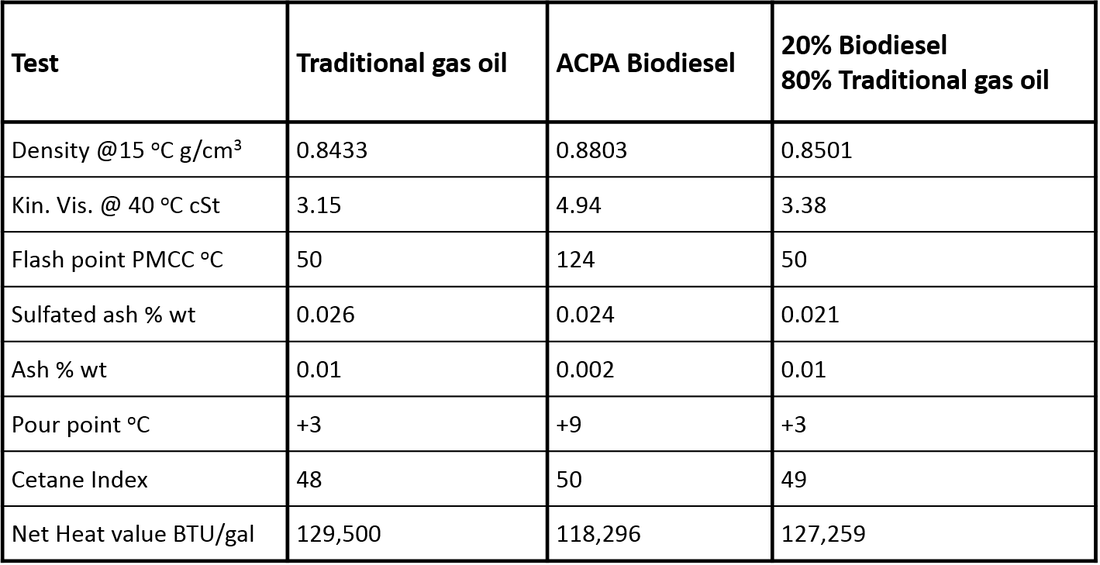

Biodiesel has a higher cetane

number, which means that biodiesel fuel will ignite more easily in a

diesel engine while also reducing engine noise. Biodiesel’s higher cetane number resulting in a difference in overall fuel economy.

With

over 16 million miles of testing by various groups and agencies, it has

been demonstrated that biodiesel usage produces a similar level of

torque, horsepower and fuel economy as that achieved by using

conventional diesel fuels.